This is a guest blog on The Cleaning Guide by:

Ian Sheppard

Sales Manager, Spring Europe LTDIan works with Spring, the electronics company that produce the most popular pump controllers. His expertise on controllers and electrical equipment makes him a valuable guest blogger on The Cleaning Guide

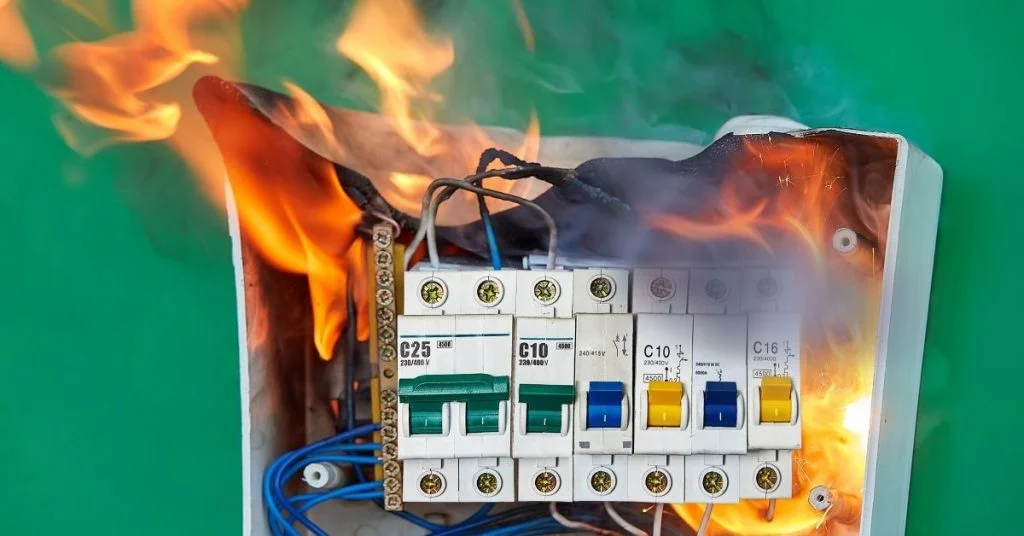

I have written in the past about the importance of fitting the correctly rated fuse. That if a fuse blows it is doing its job and the cause must be found. Simply fitting a higher rated fuse or not fitting one at all, could mean you are literally playing with fire.

Really, but I am only using 12 volts and a little 8 amp pump what could happen?

I set out to show the answer to this very question as I want to show, no matter your system, the electrical system must be maintained and properly protected with the correct fuse. The consequences of not fitting a fuse and or overrating can be dire.

I have recently carried testing in this area. I used the following set up

- a 110AH 12V Numax battery.

- 1mm Tri cable rated to 18amp max

- Cable temp rating 105C

- Shurflow pump 100PSI 5.2 LPM rated to 8 amps

- Voltmeter to measure load

To this end, I then carried out two tests as follows

Test One

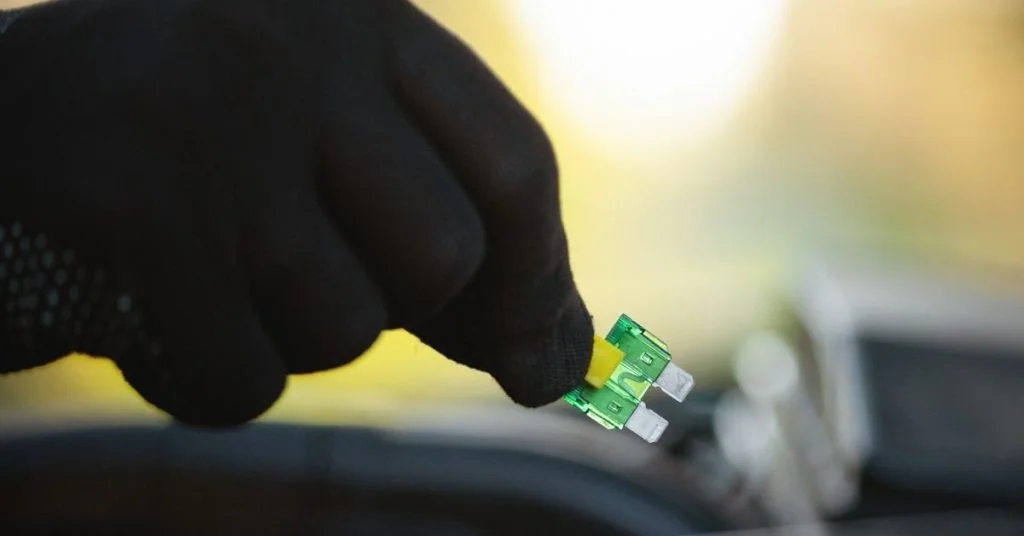

With a correctly rated 7.5 amp fuse fitted inline on the battery +12V (Red) cable. I replicated a common cable fault by connecting the Pump +12V (Brown) to ground (Negative terminal). The fault being replicated is a cable core or bare connector touching a metal part of the vehicle that is grounded.

The 7.5 amp fuse opened instantly due to the short created by the brown being grounded. All power to the Pump and Short were instantly cut preventing a dangerous build up of heat.

The short circuit to the ground was removed and the fuse was replaced with a new 7.5amp rated fuse. The pump powered up as it should and operated normally.

Conclusion

A correctly rated fuse had opened due to the short as designed fully protecting the system cabling, pump and system..

Test Two:

WARNING: Do not attempt to replicate this test, this test was performed under laboratory conditions with the required safety equipment to hand.

This time, the fuse was removed. I repeated the above test by connecting the pump +12V (Brown) to a ground. The results were as follows

- Battery voltage plummeted from 12.6V to 7.6V

- As voltage was now below 9V the pump stopped.

- The initial failure point was the connector between the pump +12 (positive) and the short to battery negative ground. This is 11 seconds after the short.

- After 20 seconds the connector and cable begin to smoke. The smoke is acrid and cable temperature is now 120C

- As the cable continued to heat the casing blistered and the blistering started to move toward the battery.

- 48 seconds following the short the positive cable from the battery is now producing thick toxic smoke. The cable core was now glowing red hot and it began to slice through the battery outer casing.

- As the fault continues various parts of the cable reached 227C.

- Note: A battery contains sulphuric acid should the red hot cable core come into contact highly toxic gasses will occur in the back of the vehicle.

- With no fuse to prevent current being supplied to the fault, heating will continue unchecked unless the cable breaks, to cut the current.

- Any flammable item e.g. clothes, documents, copy of the newspaper that come into contact with the red hot cable core will burst into flame.

- In a contained space the fire will burn until either the air supply or flammable materials are exhausted.

The question is how long will this burn?

How quickly can you get back to the van?

Most importantly How will you stop it? Cut the cable? Pull the connector off?

What if the back of the vehicle is now in flames? Opening the door will feed the flames.

Bear in mind the cables used were temperature rated to 105C and max rated to 18 amps. This rating was quickly exceeded as the fault drew a high current from the battery. The draw was sufficient to instantly pull the battery voltage down by 5 volts.

Conclusion

With no inline fuse, there is nothing to prevent a catastrophic failure due to the pump (Brown) shorting to ground, most likely on a van panel or metal frame. This can happen even if you have just had a pump and a switch connected.

As above the temperatures quickly exceeded the maximum ratings of cables, connectors and connectors Temperature reached a high of 227C. Although the cables themselves are unlikely to flame. Any combustible materials in contact with the cables such as textile or paper at this point could have caught fire very quickly.

Final Words

Both these tests underline the importance of not only fitting the correctly rated fuse but also the importance of maintaining that protection and cable condition. Overrating or not fitting the fuse at all as seen here will have serious consequences.

–Not fitting a fuse means your business could literally go up in smoke.